Preparing for glue

Prior to being able to glue the stack I had to make provisions to be able to mount the baffle with the speakers attached. To be able to repeat this with precision I made several templates for this task. One of which can be seen above. Preparing for glue is essential, as after the glue stage nothing can be altered that easily anymore.

The idea was to have a removable baffle to be able to service drivers when needed. It also allows changes to the damping materials and general maintenance.

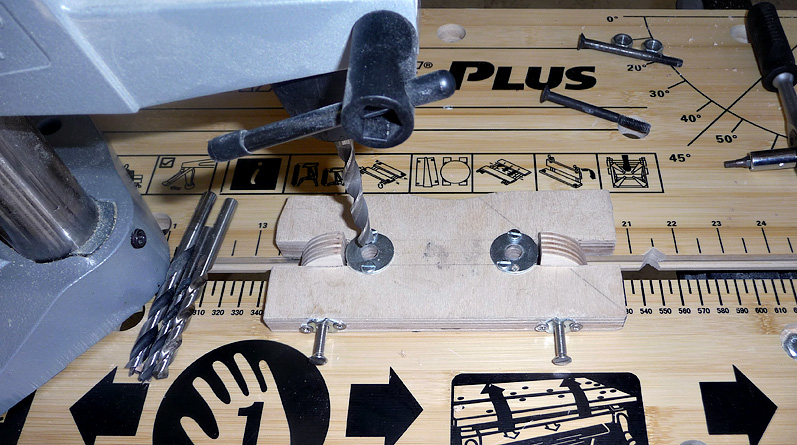

Here’s a view of the baffle mount I had planned to use, the final version is very close to this, only the nuts I used changed to t-nuts embedded in a piece of square plywood

The Baffle construction

The baffle consists of two separate pieces of aluminium with mass loaded vinyl in between the aluminium baffles and also between the total baffle and the enclosure. Total thickness of the baffle including the mass loaded vinyl layers is just shy of 1″. The inner baffle holding the drivers is floating between the enclosure and the front aluminium (beauty) plate. This gives a well damped front baffle for it’s intended full range use. It also minimises the transmission of resonances from the baffle to the enclosure.

The backside of the baffle without the Mass loaded Vinyl layer showing air flow around the driver

With the plans for the baffle construction complete I was ready for the next step. The actual gluing of the stack.